Product Description

HZS50 concrete batching plant is a medium-sized concrete mixing equipment with a theoretical production capacity of 50 cubic meters per hour. It is mainly used for producing concrete of various strength grades and is widely applied in construction projects, road and bridge construction, water conservancy works, and more. This plant adopts advanced design concepts and manufacturing technology, featuring a high degree of automation, high production efficiency, excellent mixing quality, and strong reliability.

Working Principle

HZS50 concrete batching plant operates through a centralized control system that automatically handles batching, conveying, mixing, and discharging. Materials are weighed precisely according to preset formulas and conveyed into a JS1000 twin-shaft compulsory mixer for uniform mixing before the final concrete is discharged.

Parts of HZS50 Concrete Batching Plant

Batching System: Includes aggregate batching machine, cement silo, water tank, additive tank, and corresponding measuring devices to ensure accurate dosing of all raw materials.

Conveying System: Composed of belt conveyors, screw conveyors, and lifting equipment, responsible for transporting materials from the batching system to the mixing unit.

Mixing System: Equipped with a JS1000 twin-shaft compulsory mixer, which provides high mixing efficiency and excellent mixing quality, suitable for producing various types of concrete.

Control System: Powered by a PLC controller and operated through a touchscreen interface, it enables full automation of the plant, including precise control and monitoring of batching, mixing, conveying, and discharging processes.

Pneumatic System: Supplies power to pneumatic components of the plant, such as for opening and closing discharge gates and batching hopper doors.

Steel Structure System: Includes the plant frame, silo supports, and platforms, all made from high-strength steel, ensuring excellent structural stability and seismic resistance.

Advantages & Features

High Production Efficiency: With advanced batching and mixing technology, the plant can quickly and accurately produce concrete, reaching an output of 50 cubic meters per hour, meeting the needs of medium-scale construction projects.

Excellent Mixing Quality: The twin-shaft compulsory mixer provides strong mixing force, ensuring thorough blending of materials. The resulting concrete has high uniformity and low strength variability, guaranteeing consistent quality.

High Degree of Automation: The control system enables fully automated operation, minimizing manual intervention, reducing labor intensity, and improving production stability and reliability. It also features fault self-diagnosis, allowing timely detection and resolution of issues during operation.

Strong Reliability: Key components are made from high-quality materials using advanced manufacturing techniques. For example, the mixer blades and liners are made of wear-resistant materials, extending the service life of the equipment. The overall structural design is rational and stable, suitable for harsh working environments.

Good Environmental Performance: Equipped with efficient dust removal devices, such as pulse bag filters, the plant significantly reduces dust emissions and environmental impact. Additionally, its wastewater and waste material recycling system allows for water reuse and proper disposal of residues, meeting environmental protection standards.

Technical Specifications

| Model | HZS25 | HZS35 | HZS50 | HZS75 | HZS60 | HZS90 | HZS120 | HZS180 | |

|---|---|---|---|---|---|---|---|---|---|

| Theoretical productivity | 25m³/h | 35m³/h | 50m³/h | 75m³/h | 60m³/h | 90m³/h | 120m³/h | 180m³/h | |

| Mixer model | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | JS2000 | JS3000 | |

| Mixer capacity | 0.5m³ | 0.75m³ | 1m³ | 1.5m³ | 1m³ | 1.5m³ | 2m³ | 3m³ | |

| Batching machine model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD1600 | PLD2400 | PLD3200 | PLD4800 | |

| Max.size of aggregate | ≤40/50mm | ≤40/50mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | |

| Discharging height | 1500-3800mm | 1500-3800mm | 3800mm | 4100mm | 4100mm | 4100mm | 4100mm | 4100mm | |

| Aggregate metering range and accuracy | 0-1500kg±2% | 0-2000kg±2% | 0-2000kg±2% | 0-3000kg±2% | 0-2000kg±2% | 0-3000kg±2% | 0-3000kg±2% | 0-4000kg±2% | |

| Cement metering range and accuracy | 0-300kg±1% | 0-500kg±1% | 0-800kg±1% | 0-900kg±1% | 0-800kg±1% | 0-900kg±1% | 0-1200kg±1% | 0-1800kg±1% | |

| Water metering range and accuracy | 0-200kg±1% | 0-300kg±1% | 0-300kg±1% | 0-400kg±1% | 0-300kg±1% | 0-500kg±1% | 0-500kg±1% | 0-800kg±1% | |

| Additive metering range and accuracy | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-80kg±1% | 0-100kg±1% | |

| Total Power | 50.25kw | 64.4kw | 78.7kw | 101kw | 105kw | 145kw | 210kw | 260kw | |

| Power | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | |

| Dimension(mm) | 11600✖13000✖17200 | 12900✖13000✖17200 | 18000✖10500✖17200 | 31500✖13000✖17200 | 28400✖10500✖18700 | 58500✖12300✖18700 | 60100✖13700✖18700 | 43500✖24000✖18700 | |

Applications

Urban housing and industrial building projects

Road and bridge construction

Water conservancy and coastal defense

Precast concrete plants and commercial supply

Temporary on-site concrete production for projects

Factory delivery of HZS50 Concrete Plant

Production Lead Time: Typically 7–15 working days, depending on the specific order requirements.

Packaging Method: Standard export packaging with reinforced protection for key components.

Factory Testing: All equipment undergoes rigorous debugging and testing to ensure reliable performance.

Supporting Documents: Detailed equipment manuals, operation and maintenance guides, and spare parts lists are provided to the customer.

Transportation: By land or sea, with packing lists and container loading diagrams supplied.

Delivery Options: Offers both complete machine delivery and component shipment, with support for on-site assembly by the customer.

Optional Configurations: Each HZS50 batching plant is customized to meet the customer's specific needs. Variations in configuration mean every HZS50 plant is unique!

Service

Technical Support: Installation, commissioning, and operation training are provided.

Warranty: 12-month warranty for the main machine, excluding wear parts.

Spare Parts Supply: Genuine spare parts are kept in stock for quick response to customer needs.

Remote Support: Online troubleshooting and remote control services help customers resolve issues promptly.

Installation & Commissioning: Remote technical support is available, or experienced engineers can be dispatched on-site as needed.

FAQ

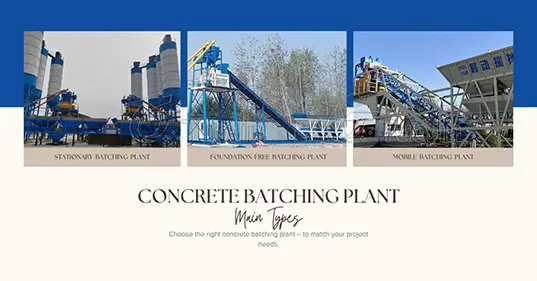

1. What is a concrete batching plant?

A concrete batching plant is an integrated facility used to mix various ingredients—such as cement, water, sand, gravel, and additives—to produce concrete in a centralized and controlled manner. It ensures accurate proportioning and high mixing quality, which is essential for construction projects ranging from small buildings to large infrastructure works. Batching plants are available in different types (stationary, mobile, compact) and capacities to suit different project needs.

2. Can the HZS50 plant be customized?

Yes, we offer customization for color, number of aggregate bins, control system brand, and more.

3. How much space does an HZS50 concrete batching plant require?

The land area for an HZS50 concrete batching plant typically ranges from 3000 to 5000 square meters, depending on the configuration of the equipment and the layout of the site.

4. What should be considered for the daily maintenance of the equipment?

Daily maintenance primarily includes regularly checking various components of the equipment, such as the wear of the mixer blades and liners, the tension of the belt conveyor, and the lubrication of various points. Additionally, it is important to keep the equipment clean by promptly removing dust and debris, and regularly replacing lubricating oil and worn parts.

5. Can the concrete mix ratio be adjusted according to different project requirements?

Yes. The HZS50 concrete batching plant is equipped with a control system that includes recipe management functionality. Operators can easily set and modify the concrete mix ratio on the control interface to meet various strength grades and performance requirements, allowing for flexible concrete production based on specific project needs.

6. How much does an HZS50 concrete batch plant cost?

The price of an HZS50 concrete batching plant generally ranges from $45,000 to $80,000 USD, depending on the specific configuration, brand, country of origin, automation level, and optional components such as:

Number of aggregate bins (2-bin / 3-bin / 4-bin)

Type and number of cement silos

Dust collection systems

Control system (PLC automation, software features)

Transportation and installation services