What is JZC350 concrete mixer?

JZC350 drum concrete mixer is a medium-to-small-sized concrete mixing equipment that operates on the self-falling mixing principle. It is suitable for mixing various types of plastic and semi-dry hard concrete. With a compact structure, easy operation, and convenient mobility, it is widely used on construction sites, road and bridge projects, and precast component factories. It is especially ideal for rural or temporary construction sites.

How does JZC350 concrete mixer work?

JZC350 features a structure that mixes when rotating forward and discharges when rotating in reverse:

During mixing: The motor rotates forward, driving the mixing drum to rotate in the same direction via gears. Inside the drum, the materials are lifted by the blades and fall freely, achieving thorough mixing.

During discharging: The motor rotates in reverse, causing the drum to rotate in the opposite direction, and the mixed concrete is automatically poured out through the discharge outlet.

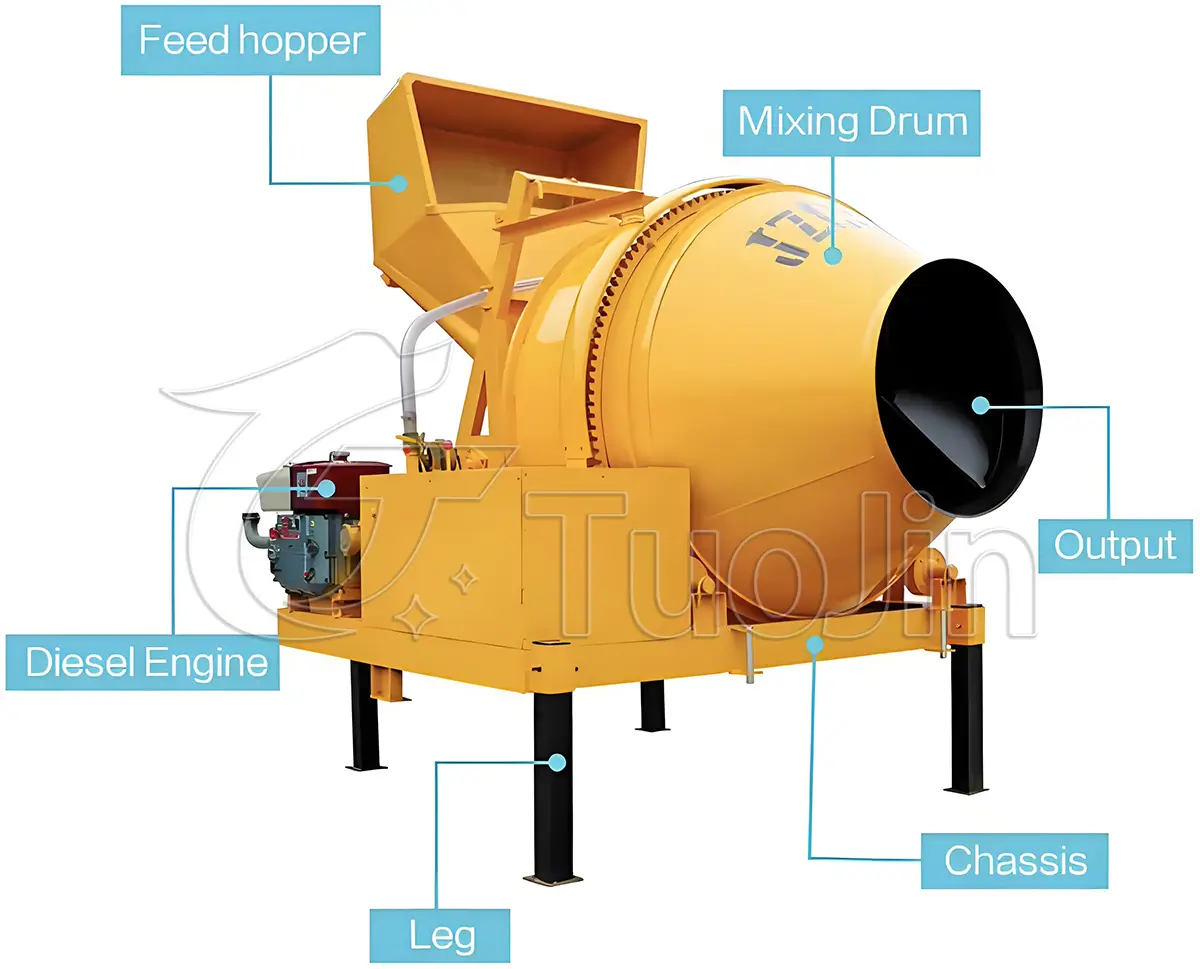

Parts of JZC350 Concrete Mixer

1. Mixing Drum: A double-cone structure with built-in mixing blades, which rotates to mix and discharge the concrete.

2. Driving System: Composed of a motor, reducer, and gears, it drives the rotation of the mixing drum.

3. Feeding System: Equipped with a hopper, which lifts materials using a hoisting mechanism.

4. Discharging Mechanism: Utilizes reverse gear control to rotate the drum in the opposite direction for automatic discharging.

5. Wheels and Support Frame: Allows for short-distance movement, making it convenient to relocate on construction sites.

6. Electric Control System: Manages operations such as mixing, feeding, and discharging, with a simple and intuitive control panel.

Advantages & Features

1. Compact Structure: Small footprint, ideal for construction sites with limited space.

2. Easy Operation: High degree of automation; can be operated by a single person.

3. Uniform Mixing: Blades inside the drum are reasonably arranged, ensuring high mixing quality.

4. Energy Efficient and Durable: Moderate motor power, low operating cost, and long service life.

5. Convenient Maintenance: Few wearing parts, easy to repair, and spare parts are readily available.

Technical Specifications

| Model | JZC350 | JZC400 | JZC500 | |

|---|---|---|---|---|

| Discharging Capacity | 350L | 400L | 500L | |

| Loading Capacity | 560L | 640L | 800L | |

| Productivity | 10-14m³/h | 12-16m³/h | 18-20m³/h | |

| Power of mixing motor | 5.5kw | 5.5kw | 7.5-11kw | |

| Power of lifting motor | 4.5kw | 4.5kw | 5.5kw | |

| Power of water pump | 0.55kw | 0.55kw | 0.75kw | |

| Accuracy of water supply | Error≤2% | Error≤2% | Error≤2% | |

| Speed of mixing drum | 14r/min | 14r/min | 13r/min | |

| Size(L*W*H) | 2760✖2170✖3000mm | 2940✖2240✖2880mm | 3320✖2460✖3650mm | |

| Weight | 1950kg | 2160kg | 3100kg | |

Applications

Urban and rural construction sites

Bridge, road, and tunnel construction

Precast concrete component factories

Rural housing construction projects

Small-scale municipal engineering projects

Operation and Maintenance Guidelines

Before operation, check the electrical system, lubrication system, and ensure the drum rotates properly.

Follow the specified mix ratio during operation; overloading is strictly prohibited.

Clean out residual materials from the drum after each use to prevent hardening.

Regularly inspect bearings, chains, gears, and other components for wear, and replace or lubricate as needed.

The electrical control box should be protected from rain and dust, and ensure proper grounding.

Factory delivery of JZC350 Concrete Mixer

Delivery Time: For standard models, shipment is usually made within 3 to 7 working days after receiving the deposit, depending on the order quantity.

Packaging: Standard export packaging; key components such as the electric control box and reducer are packed in wooden cases to ensure safe transportation.

Shipping Methods: Land transportation or container sea shipping is available. Customers may choose their own logistics provider or request assistance from us.

Accessories Included: Product certificate of conformity, user manual, and a list of wearing parts are included with the shipment.

Pre-shipment Inspection: All equipment undergoes no-load testing and quality inspection before delivery to ensure stable performance and compliance with standards.

Service

Technical Guidance: Detailed installation videos and operation manuals are provided. If needed, engineers can offer remote video support or on-site assistance.

After-sales Warranty: The whole machine is covered by a 12-month warranty. Core components such as the reducer, motor, and electric control system are eligible for free replacement within the warranty period.

Spare Parts Supply: Long-term supply of original spare parts with quick response and timely delivery. Common wearing parts can be shipped together with the main machine.

Customer Training: Free training materials on operation and maintenance are provided to ensure that customer personnel can operate and maintain the equipment independently.

Customization Service: Loading method, motor voltage, appearance color, and logo can be customized according to customer requirements to achieve product personalization.

FAQ

1. What is the rated capacity of the JZC350 concrete mixer?

The JZC350 is a self-falling drum concrete mixer with a rated discharge capacity of 350 liters, capable of mixing approximately 0.35m³ of concrete per batch. Its feeding capacity is 560 liters, making it ideal for small projects or rural house construction.

2. Does this mixer require an external power supply? What is the power consumption?

The JZC350 typically uses three-phase 380V AC power, with a motor power of about 5.5 kW. If three-phase electricity is unavailable on site, a diesel engine-driven model is also available (subject to manufacturer configuration).

3. What is the drum rotation speed? How is the mixing performance?

The drum rotates at 14–16 RPM, using the self-falling mixing principle (materials fall freely to mix). It is suitable for standard concrete and mortar, though the efficiency is slightly lower than that of a forced-type mixer.

4. What is the weight of the machine? Is it easy to move?

The total machine weight is about 1800–2000 kg. It is equipped with a tire-mounted tow frame and can be moved using a tractor or manual towing, making it suitable for job sites that require frequent relocation.

5. What should be noted for daily maintenance?

Clean the drum after each use to prevent concrete hardening.

Regularly check the oil level in the gearbox and lubricate the bearings.

When not in use for a long time, disconnect the power and cover the machine to prevent rain and rust.

6. What is the difference between JZC350 and JZC500?

The JZC500 has a larger capacity (0.5 m³ per batch) and higher motor power (about 7.5 kW), making it more suitable for medium-scale projects. However, it is also larger in size and higher in price.