What is a screw conveyor

Screw conveyor is a core piece of equipment used in concrete batching plants for conveying powdered and granular materials. It transports materials in a sealed space through the rotation of screw blades, enabling horizontal, inclined, or vertical movement. In batching plants, it is primarily used for conveying dry powders such as cement, fly ash, and slag powder. It features dust prevention, energy efficiency, and precise metering capabilities.

How does a screw conveyor work

When the motor starts, power is transmitted to the screw shaft through the reducer. The rotating screw blades push the material axially along the tube. Under the combined action of gravity and screw thrust, material enters through the inlet, moves forward along the blade direction, and is eventually discharged through the outlet. The sealed tubular structure effectively prevents dust dispersion, enabling environmentally friendly conveying.

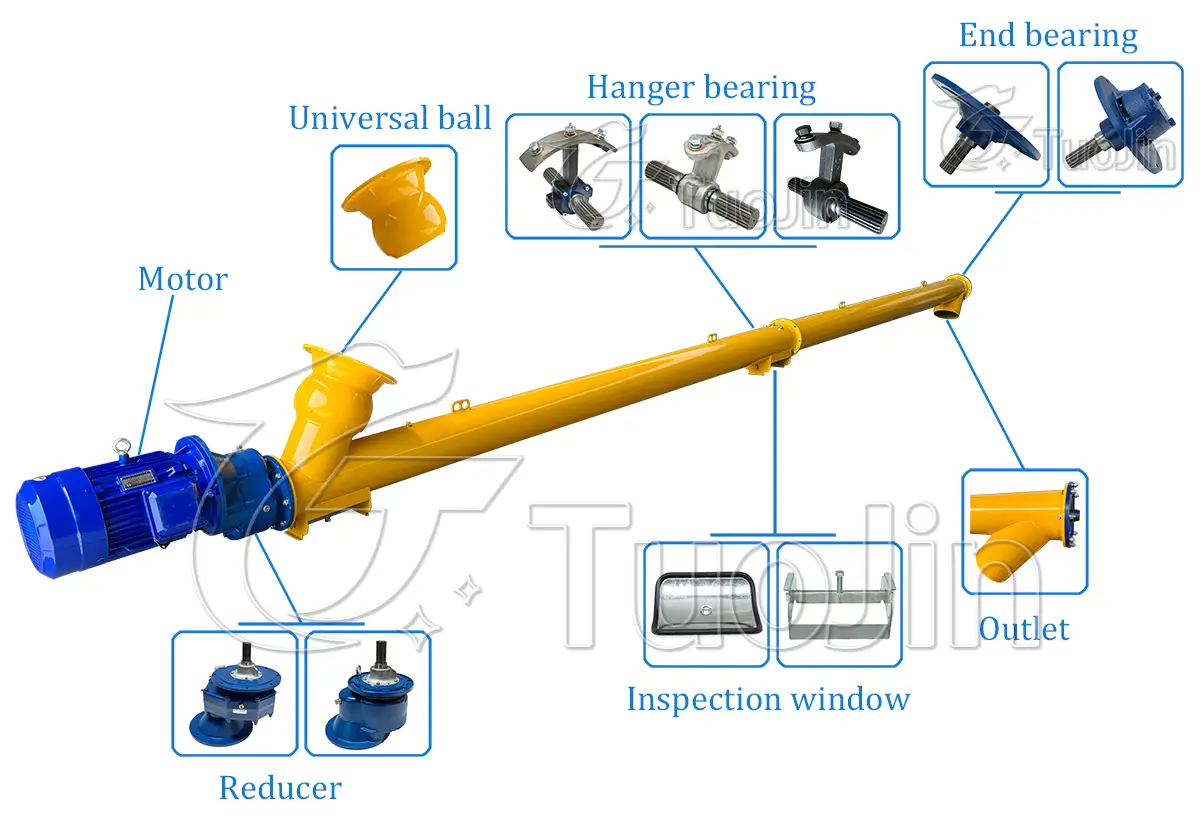

Parts of Screw Conveyor

1. Screw Blade (Helix)

Typically made by welding continuous strip or helical steel plates.

Constructed from wear-resistant carbon steel or stainless steel, offering strong abrasion and corrosion resistance.

Depending on the material being conveyed, it can be designed as a solid shaft or shaftless type.

2. Conveying Tube (Casing)

Features a sealed tubular structure to effectively prevent material leakage or moisture-induced caking.

Smooth internal surface facilitates smooth material flow.

3. Inlet and Outlet

Installation positions can be customized based on on-site requirements.

The inlet is usually connected to the bottom flange of the cement silo, while the outlet is linked to the powder weighing system of the batching plant.

4. Drive Unit

Comprises motor, reducer, and coupling.

The drive motor is typically a three-phase asynchronous motor, providing stable torque output.

Commonly used reducers include helical gear reducers or cycloidal gear reducers.

5. Hanger Bearings and End Bearings

Support the screw shaft and reduce friction during operation.

Bearings are sealed to prevent dust ingress.

6. Cleaning Port

Located at the bottom of the tube body for easy maintenance and removal of residual material, preventing blockages.

Advantages & Features

1. Excellent Sealing Performance

The tubular sealed structure effectively prevents powder leakage and avoids environmental pollution.

2. High Conveying Efficiency

Optimized screw angle and rotation speed design ensure continuous and stable conveying.

3. Flexible Installation

Can be installed horizontally, inclined, or in multiple sections to suit complex working conditions.

4. Long Service Life

Key components are made from high-strength materials for superior wear resistance and durability.

5. Easy Maintenance

Equipped with inspection and cleaning ports for convenient routine cleaning and maintenance.

6. Strong Compatibility

Seamlessly connects with various types of cement silos and concrete batching plants.

Technical Specifications

| Model | LSY168 | LSY219 | LSY273 | LSY323 | LSY407 | |

|---|---|---|---|---|---|---|

| Diameter of screw | 168mm | 219mm | 273mm | 323mm | 407mm | |

| Conveying Distance | 3-13m | 3-15m | 3-15m | 3-15m | 3-15m | |

| Tube thickness | 3-8 | 3-8 | 3-8 | 4-8 | 4-8 | |

| Rotation speed | 288r/min | 288r/min | 205r/min | 144r/min | 144r/min | |

| Diameter of body | Φ168mm | Φ219mm | Φ273mm | Φ323mm | Φ407mm | |

| Working Angle | ≤60° | ≤60° | ≤60° | ≤60° | ≤60° | |

| Conveying Capacity | 25t/h | 35t/h | 50t/h | 75t/h | 110t/h | |

| Motor Model | Y132M-4 | Y160M-4 | Y160L-4 | Y180L-4 | Y200L-4 | |

| Motor Power | 2.2-15kw | 2.2-22kw | 3-22kw | 5.5-22kw | 5.5-22kw | |

Applications

Applicable to various specifications of concrete batching plants (e.g., HZS35, HZS60, HZS120, etc.)

Suitable for conveying bulk cement, fly ash, slag powder, and other powder materials

Powder conveying systems in industries such as construction materials, chemical engineering, and metallurgy

Key Selection Points

When selecting a screw conveyor for a concrete batching plant, the following factors should be considered:

Type and flowability of the material to be conveyed

Required conveying capacity and length

Available installation space and angle

Model of the connected cement silo and its discharge method

Whether special requirements such as explosion-proof or corrosion resistance are needed

Factory delivery of Screw Conveyor

Production Lead Time: Typically 7–15 working days, depending on the specific order requirements.

Packaging Method: Standard export packaging with reinforced protection for key components.

Factory Testing: All equipment undergoes rigorous debugging and testing to ensure reliable performance.

Supporting Documents: Detailed equipment manuals, operation and maintenance guides, and spare parts lists are provided to the customer.

Transportation: By land or sea, with packing lists and container loading diagrams supplied.

Delivery Options: Offers both complete machine delivery and component shipment, with support for on-site assembly by the customer.

Optional Configurations: Each screw conveyor is customized to meet the customer's specific needs. Variations in configuration mean every screw conveyor is unique!

Installation and Operation Recommendations

Before installation, ensure the bottom of the cement silo legs is securely connected to the conveyor support.

It is recommended to keep the installation angle within 20° to ensure smooth material flow.

Check the oil level in the reducer before operation, and replace the lubricant regularly.

Before each shift, check the motor temperature rise and ensure the screw shaft operates smoothly.

FAQ

1. What materials are screw conveyors mainly used to transport?

Screw conveyors are mainly used to transport dry powdery or granular materials such as cement, fly ash, and mineral powder. They are an important part of the powder conveying system in concrete batching plants.

2. Can the length of the screw conveyor be customized?

Yes, it can. Standard lengths include 3 meters, 6 meters, and 9 meters. Users can also customize the length according to the layout requirements of the batching plant. The maximum length is generally no more than 12 meters to ensure conveying efficiency and equipment stability.

3. What are the available diameter specifications for screw conveyors?

Common specifications include φ168mm, φ219mm, φ273mm, and φ323mm. The selection should be based on the required conveying capacity and material characteristics.

4. How to make a screw conveyor?

Manufacturing a screw conveyor requires components like a helical blade (flighting), pipe or trough, motor, gearbox, inlet and outlet, and bearing supports. It also involves welding, machining, and assembling processes. For industrial use, it's recommended to purchase from professional manufacturers.

5. How much is a screw conveyor?

The price of a screw conveyor varies based on its diameter, length, material, motor power, and application. Typical prices range from $300 to $1,500 per unit. Customized designs may cost more.

6. How to assemble a screw conveyor?

Assembly involves connecting the screw shaft to the motor and gearbox, aligning and mounting the pipe or trough, securing bearings and hangers, and sealing the inlets and outlets. Follow the manufacturer's manual for correct procedures and safety checks.

7. How to install a screw conveyor?

Ensure the foundation is level and stable. Align the conveyor with the hopper or silo, connect the motor and electrical components, and check for smooth rotation before operation. A tilt angle below 20° is ideal for efficient performance.

8. Do you supply screw conveyors made in China?

Yes, TuoJin all screw conveyors are Made in China, ensuring competitive pricing and reliable quality. We export to over 30 countries worldwide.

9. Is your screw conveyor suitable for concrete batching plants?

Absolutely. Our China cement screw conveyors are specially designed to integrate seamlessly with concrete batching plants, ensuring efficient powder transport and minimal maintenance.

10. Do you offer screw conveyors for sale directly from factory?

Yes. As a China screw conveyor factory, we offer direct sales with customizable options, fast delivery, and after-sales support.