As modern construction projects increasingly pursue efficiency and high quality, the performance of concrete mixing equipment directly impacts construction quality and project progress. As a key player among mixing equipment, TUOJIN Machinery's Twin Shaft Concrete Mixer has become a star product among overseas distributors, thanks to its efficient mixing capability, stable discharge quality, and exceptional durability. It is now widely used in various medium and large-scale construction projects and precast concrete production lines.

What is a Twin Shaft Concrete Mixer?

A twin shaft concrete mixer is a type of compulsory mixing equipment that uses two horizontally arranged and synchronously rotating shafts to mix materials. The two counter-rotating shafts drive the mixing blades to shear, overturn, and blend the materials, enabling the concrete to reach a uniform and consistent state in a short time. This equipment is widely used for mixing dry hard concrete, plastic concrete, lightweight aggregate concrete, and various types of mortar.

Key Advantages of Twin Shaft Concrete Mixers

1. Uniform Mixing with Higher Efficiency

The twin-shaft structure enables 360-degree, dead-zone-free mixing, allowing cement, aggregates, water, and additives to be evenly distributed quickly, thereby improving the strength and workability of concrete.

2. Sturdy Structure with Strong Adaptability

Equipped with thickened mixing arms, high-strength shaft-end sealing, and a durable reduction system, the equipment boasts a long service life and stable operation under harsh working conditions.

3. Quick Discharge, Time-Saving

Designed with hydraulic or pneumatic discharge systems, it ensures fast discharge after mixing, boosting overall production efficiency.

4. Easy Maintenance and Smart Operation

Comes with a lubrication system and automatic monitoring, simplifying daily maintenance and reducing failure rates. It also supports intelligent control systems for remote operation and data monitoring.

5. Wide Range of Applications

Twin shaft mixers are now widely used in ready-mix concrete plants, bridge projects, tunnel construction, precast factories, road construction, and water conservancy projects. Whether mixing high-strength or large aggregate concrete, twin shaft mixers are up to the task and highly favored by contractors and equipment rental companies.

Common Models and Selection Guidelines

Currently, the market offers a range of twin shaft concrete mixers classified by mixing capacity, with common models including:

JS500: Suitable for small- to medium-sized projects or stand-alone use; 0.5 m³ per batch; cost-effective and ideal for rural construction and brick factories.

JS750: 0.75 m³ per batch; suited for medium-sized mixing plants or construction sites.

JS1000: 1 m³ per batch; commonly used as the main mixer for HZS60 mixing plants; widely applied.

JS1500: 1.5 m³ per batch; standard configuration for HZS90 mixing plants.

JS2000 and above (e.g., JS3000, JS4000): Designed for large mixing stations and precast concrete factories; ideal for continuous high-volume production.

Selection Advice:

1. Choose According to Project Scale

For small or temporary projects, JS500 or JS750 are sufficient. For medium to large-scale sites, JS1000 and above are recommended to ensure efficient concrete supply.

2. Match Mixer Model to Batching Plant Specification

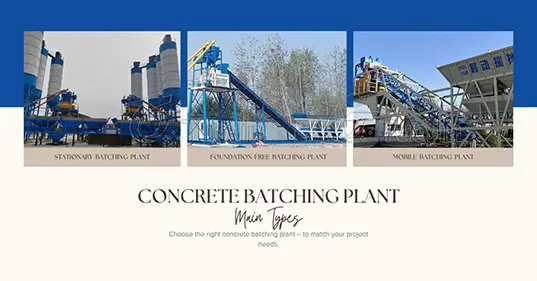

If a concrete batching plant is already established or planned, choose the mixer model based on the plant type (e.g., HZS60, HZS90) to ensure system compatibility.

3. Consider Material Characteristics

For projects involving lightweight aggregates, high-strength concrete, or large-grain aggregates, choose a higher-powered and more wear-resistant mixer.

4. Focus on After-Sales Support and Spare Parts Supply

Select products from reputable brands with interchangeable parts and responsive after-sales service to reduce downtime and maintenance costs.

With the growing emphasis on green construction and intelligent manufacturing, this "mixing pioneer" is expected to play an even more vital role in the future of the construction industry. We will continue optimizing its mixing structure and control systems to meet the personalized needs of customers worldwide.