As the construction industry continues to evolve, concrete batching plants—critical equipment in modern construction—are drawing increasing attention from contractors and investors alike. To meet the diverse demands of various projects and site conditions, concrete batching plants come in multiple types. This article provides an overview of concrete batching plants, their classifications, and the features and benefits of each type, to help customers choose the most suitable solution.

What is a Concrete Batching Plant?

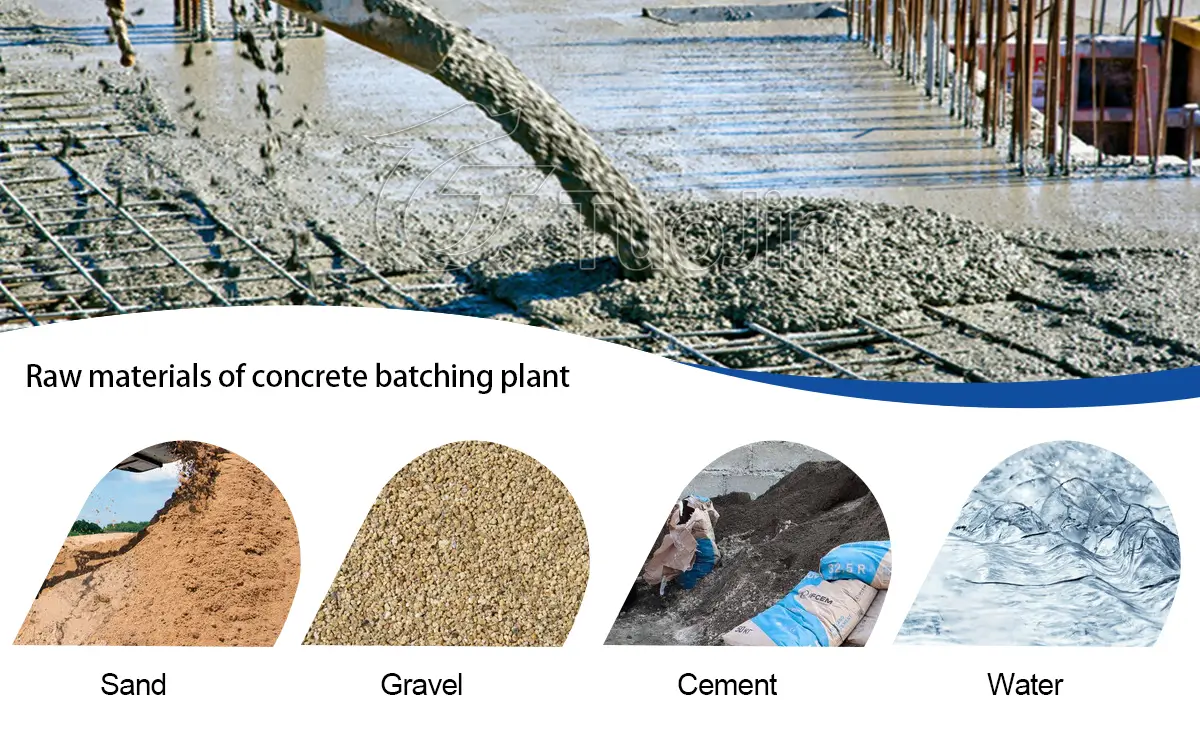

Concrete batching plant is a system that centralizes concrete production. It typically consists of a mixer, aggregate batching machine, cement silo, conveying system, weighing system, and control system. Its primary function is to accurately weigh and uniformly mix materials such as sand, gravel, cement, and water in accordance with a pre-set mix ratio, producing ready-mixed concrete that meets specified standards.

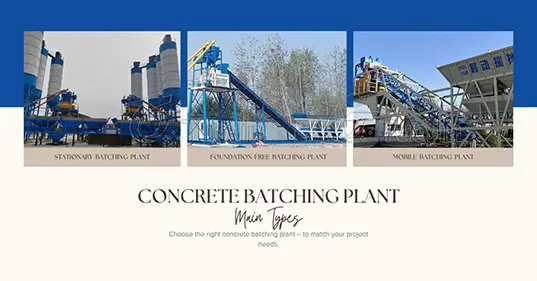

Main Types of Concrete Batching Plants

Based on installation methods and operational flexibility, concrete batching plants are generally classified into three categories:

Stationary Concrete Batching Plant (HZS Series)

Foundation-Free Concrete Batching Plant (MHZS Series)

Mobile Concrete Batching Plant (YHZS Series)

Stationary Concrete Batching Plant (HZS Series)

Features and Advantages:

1. High Production Capacity: Suitable for large-scale construction projects such as high-rise buildings, highways, bridges, and water conservancy works, with output ranging from 60m³ to 180m³ per hour.

2. Stable Operation: Built on a solid foundation, the structure is compact and durable, ideal for long-term fixed-site operation.

3. High Automation: Equipped with intelligent control systems for automated batching, mixing, and discharging, ensuring easy operation and high efficiency.

4. Excellent Quality Control: Delivers stable and consistent concrete quality, meeting stringent quality requirements for major projects.

Recommended for: Urban ready-mix concrete enterprises and large-scale infrastructure projects.

Foundation-Free Concrete Batching Plant (MHZS Series)

Features and Advantages:

1. No Foundation Required, Quick Installation: Requires only ground leveling and hardening, saving significant time and costs on foundation construction.

2. Modular Design, Easy Relocation: Components are modular and integrated for flexible transport and quick site transitions.

3. Cost-Effective: Eliminates civil foundation costs, making it ideal for small to medium contractors.

4. Eco-Friendly: Optional enclosed structures and dust removal systems help reduce noise and dust emissions.

Recommended for: Rural infrastructure, mobile construction sites, and temporary engineering projects.

Mobile Concrete Batching Plant (YHZS Series)

Features and Advantages:

1. Trailer-Mounted Design: All systems are integrated on a trailer chassis for excellent mobility and flexibility.

2. Ready to Use On Arrival: Can be installed and start production within hours of reaching the site.

3. Space-Saving, No Foundation: Does not require permanent construction, and occupies minimal space.

4. User-Friendly and Easy Maintenance: Simple structure for convenient operation and maintenance, especially suitable for remote regions.

Recommended for: Highway repair projects, remote mountainous areas, and temporary hydroelectric works.

How to Choose the Right Concrete Batching Plant?

When selecting a concrete batching plant, consider the following factors:

1. Project Size and Output Requirements: Large projects suit stationary plants, while mobile and foundation-free types are better for smaller, flexible jobs.

2. Site Mobility: For projects requiring frequent relocation, choose mobile or foundation-free options.

3. Budget: Stationary plants require higher upfront investment; mobile and MHZS models are more budget-friendly.

4. Installation Time: For urgent projects, mobile or foundation-free plants offer significant time-saving advantages.

5. Concrete Quality Standards: For projects with strict quality control needs, choose stationary plants with high automation and batching accuracy.

Each type of concrete batching plant has its unique strengths and application scenarios. Customers should choose the appropriate model based on project conditions, timeline, and budget to maximize return on investment. As a professional concrete equipment manufacturer, TuoJin Machinery offers tailored solutions to support efficient and sustainable project delivery.

Why Choose TUOJIN MACHINERY Concrete Batching Plants?

In today's fast-paced construction industry, choosing efficient and reliable concrete batching equipment is essential. TUOJIN MACHINERY, backed by years of expertise in the concrete machinery field, has grown into one of the industry's leading manufacturers. We are committed to customer-oriented service, ensuring smooth project execution and long-term operation through every stage—from equipment design and manufacturing to after-sales support.

Our wide range of concrete batching plants—including stationary, mobile, and foundation-free models—are suited for residential construction, roads and bridges, tunnels, and water conservancy projects. All units come equipped with advanced electric control systems that enable automated operations and smart fault diagnostics, helping users achieve high-efficiency production with ease. The core mixers use twin-shaft forced mixing technology for fast and uniform mixing. Durable wear-resistant parts extend the equipment's lifespan and reduce operating costs.

Internationally, our products have been exported to Southeast Asia, the Middle East, Africa, and South America, receiving high praise. All export models are certified under CE and ISO9001 standards, ensuring peace of mind for global clients. We also provide customized solutions, rapid delivery, remote technical support, and on-site training—offering true value to every customer.

Choosing TUOJIN means more than selecting a concrete machine—it means partnering with a professional, reliable, and dedicated team. We will continue to uphold our principles of quality first and service foremost, delivering superior products and efficient solutions for customers around the world.