In recent years, concrete batching plants have become essential equipment in the global push for infrastructure modernization. From highways and bridges to airports and skyscrapers, these plants are playing a critical role in ensuring the timely and high-quality delivery of concrete.

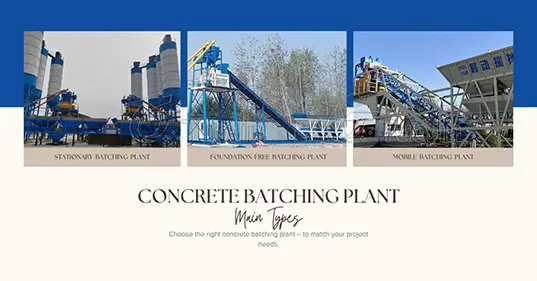

What is concrete batching plant?

A concrete batching plant is a facility used to mix various ingredients—such as sand, gravel, cement, and water—to produce ready-mix concrete. These plants are equipped with sophisticated control systems that ensure precise mixing ratios and consistent product quality.

The demand for concrete batching plants is surging in developing regions such as Southeast Asia, Africa, and Latin America, where large-scale infrastructure projects are accelerating. Mobile and foundation-free models are particularly popular in remote or temporary job sites due to their easy transportation and quick installation.

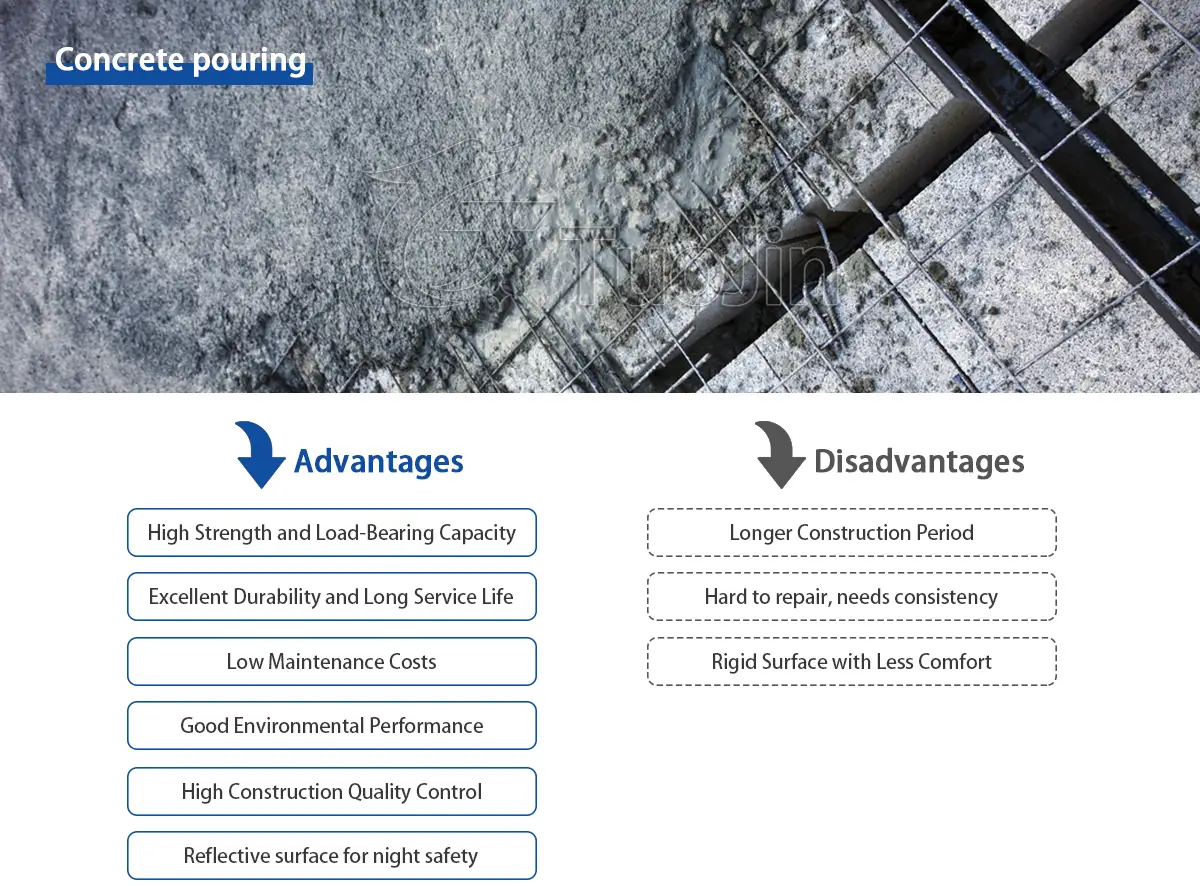

Concrete produced by batching plants is commonly used for constructing concrete pavements. These pavements are widely applied in highways, municipal roads, airport runways, and more. Below are the main advantages and disadvantages of concrete pavements made with batching plant concrete, helping customers make informed choices based on their specific needs.

✅ Advantages of Using Batching Plant Concrete for Road Construction

1. High Strength and Load-Bearing Capacity

Concrete produced by batching plants features accurate mix proportions and stable quality, with high compressive strength. It is especially suitable for heavy-load traffic areas such as truck lanes and airport runways.

2. Excellent Durability and Long Service Life

Concrete pavements are resistant to deformation and water damage. They typically last 20 to 30 years or even longer, with low maintenance requirements.

3. Low Maintenance Costs

Compared to asphalt roads, concrete pavements are less prone to potholes and do not require frequent repairs or resurfacing, reducing long-term maintenance expenses.

4. Good Environmental Performance

Concrete materials emit no dust or harmful gases and contain no volatile organic compounds (VOCs), resulting in minimal environmental impact and meeting green construction standards.

5. High Construction Quality Control

Batching plants are equipped with automated control systems that ensure consistent concrete quality. Parameters such as temperature, moisture content, and strength can be monitored in real-time, making it suitable for large-scale continuous pouring.

6. Good Surface Reflectivity and Enhanced Nighttime Safety

Concrete pavements have a light color and excellent reflectivity, which improves visibility and enhances driving safety at night.

❌ Disadvantages of Using Batching Plant Concrete for Road Construction

1. Longer Construction Period

Concrete requires curing time, typically more than 7 days to reach usable strength, which delays early opening and is less ideal for projects needing rapid completion.

2. Difficult Repairs and High Integrity Requirements

Once damaged, concrete roads are complex to repair. It's hard to perfectly match the color and texture of the original pavement, which may affect overall aesthetics.

3. Rigid Surface with Less Comfort

As a rigid pavement type, concrete provides more noticeable vibrations when vehicles pass over it, offering less riding comfort compared to flexible asphalt surfaces.

Experts in the construction industry emphasize that the efficiency and automation level of batching plants directly influence project timelines and construction costs. Modern plants now feature real-time monitoring, automated weighing, and even cloud-based data management, significantly enhancing operational performance.

As the global focus on sustainable construction grows, manufacturers are also innovating with eco-friendly designs—such as dust collection systems and energy-efficient mixers—ensuring that productivity goes hand-in-hand with environmental protection.

Industry analysts predict that the global concrete batching plant market will continue to expand steadily in the coming years, driven by smart technologies and growing demand for urban development.