Product Description

HZS25 concrete batching plant is a compact and space-saving concrete production equipment, mainly composed of a mixer, batching machine, screw conveyor, cement silo, and control system. It features high mixing efficiency, accurate measurement, and easy operation. It is widely used in small to medium-scale construction projects such as roads, bridges, and housing, making it an ideal choice for customers with limited investment budgets.

Working Principle

Aggregates are discharged from the aggregate bins of the batching station into the aggregate weighing hopper for measurement. After weighing, the aggregates are discharged onto a flat belt conveyor, which transfers them to an inclined belt conveyor. The inclined belt conveyor transports the aggregates to the waiting hopper above the mixer, where they wait for further instructions. Meanwhile, cement and fly ash are conveyed by screw conveyors to their respective weighing hoppers for measurement. Water and admixtures are delivered by a water pump and admixture pump, respectively, to their own weighing hoppers for accurate dosing.

Once all materials are measured, the control system issues a command to sequentially feed the materials into the mixer for mixing. Upon completion, the discharge gate of the mixer opens, and the concrete is discharged into the discharge hopper and then into a concrete mixer truck, entering the next working cycle.

Parts of HZS25 Concrete Batching Plant

Mixing System: Equipped with a JS500 twin-shaft compulsory mixer, which ensures uniform mixing and high efficiency.

Batching System: Uses a PLD800 batching machine, capable of measuring two or three types of aggregates.

Conveying System: Materials are fed using either a belt conveyor or a bucket elevator, allowing for a small footprint and flexible layout.

Cement System: Includes a cement silo and screw conveyor to ensure continuous and stable material supply.

Weighing System: Independent weighing of cement, water, and additives with high precision and quick response.

Control System: Fully automatic control with manual/automatic switching options, featuring a user-friendly interface for easy operation and management.

Advantages & Features

Quick Installation: The plant can be configured with either a steel beam-mounted or fixed structure. For the steel beam-mounted version, the main mixing system can be installed within just a few hours after unloading. With the addition of the control room, batching station, and other supporting facilities, the entire setup can be ready for production within two to four days.

Reasonable Design: The mixing platform, weighing platform, and hoisting system platform are all designed to ensure convenient inspection and maintenance. Even when an external protective enclosure is required, ample space is reserved for daily operations.

Small Footprint: The HZS25 plant uses a winch hoisting hopper for material feeding. The specially designed hopper and track system enables efficient loading and dumping of aggregates, significantly reducing site area requirements.

Low Investment and Easy Maintenance: The HZS25 plant requires minimal investment, occupies a small area, and involves fewer pieces of equipment. Maintenance is simple, and operation is safe and user-friendly.

Technical Specifications

| Model | HZS25 | HZS35 | HZS50 | HZS75 | HZS60 | HZS90 | HZS120 | HZS180 | |

|---|---|---|---|---|---|---|---|---|---|

| Theoretical productivity | 25m³/h | 35m³/h | 50m³/h | 75m³/h | 60m³/h | 90m³/h | 120m³/h | 180m³/h | |

| Mixer model | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | JS2000 | JS3000 | |

| Mixer capacity | 0.5m³ | 0.75m³ | 1m³ | 1.5m³ | 1m³ | 1.5m³ | 2m³ | 3m³ | |

| Batching machine model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD1600 | PLD2400 | PLD3200 | PLD4800 | |

| Max.size of aggregate | ≤40/50mm | ≤40/50mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | ≤60/80mm | |

| Discharging height | 1500-3800mm | 1500-3800mm | 3800mm | 4100mm | 4100mm | 4100mm | 4100mm | 4100mm | |

| Aggregate metering range and accuracy | 0-1500kg±2% | 0-2000kg±2% | 0-2000kg±2% | 0-3000kg±2% | 0-2000kg±2% | 0-3000kg±2% | 0-3000kg±2% | 0-4000kg±2% | |

| Cement metering range and accuracy | 0-300kg±1% | 0-500kg±1% | 0-800kg±1% | 0-900kg±1% | 0-800kg±1% | 0-900kg±1% | 0-1200kg±1% | 0-1800kg±1% | |

| Water metering range and accuracy | 0-200kg±1% | 0-300kg±1% | 0-300kg±1% | 0-400kg±1% | 0-300kg±1% | 0-500kg±1% | 0-500kg±1% | 0-800kg±1% | |

| Additive metering range and accuracy | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-50kg±1% | 0-80kg±1% | 0-100kg±1% | |

| Total Power | 50.25kw | 64.4kw | 78.7kw | 101kw | 105kw | 145kw | 210kw | 260kw | |

| Power | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | 380V 50HZ 3phase | |

| Dimension(mm) | 11600✖13000✖17200 | 12900✖13000✖17200 | 18000✖10500✖17200 | 31500✖13000✖17200 | 28400✖10500✖18700 | 58500✖12300✖18700 | 60100✖13700✖18700 | 43500✖24000✖18700 | |

Application

Concrete batching plants are essential equipment in modern construction projects, primarily used for the centralized mixing and supply of concrete. They are widely applied in the following areas:

Small-Scale Building Construction: Ideal for constructing small residential houses, commercial shops, and office buildings. On-site production of concrete ensures a timely supply and consistent quality that meets construction standards, helping to improve construction efficiency and the structural stability of buildings.

Road and Bridge Construction: Extensively used in urban road repairs, rural road paving, and small bridge construction. The plant can produce concrete with the required strength, durability, and workability to meet various road and bridge requirements, providing a solid foundation and support.

Water Conservancy Projects: Applicable to the construction of small dams, canals, water tanks, and other hydraulic structures. It can produce concrete with excellent impermeability and frost resistance, meeting the special demands of water conservancy projects, effectively preventing seepage and erosion, and extending the service life of the facilities.

Precast Component Production: Used to produce precast concrete slabs, piles, pipes, and other elements. Through precise control of mix ratios and production processes, it ensures stable quality and high dimensional accuracy, making it widely applicable in construction and municipal engineering projects.

Temporary Construction Sites: Ideal for flexible deployment in projects such as subway construction, urban renovation, and airport expansions. It can function as a small-scale ready-mix concrete station to supply fresh concrete directly to the site.

In summary, concrete batching plants are key facilities for centralized concrete production, helping improve construction efficiency and project quality. They have become standard equipment on modern construction sites.

Factory delivery of HZS25 Concrete Plant

Production Lead Time: Typically 7–15 working days, depending on the specific order requirements.

Packaging Method: Standard export packaging with reinforced protection for key components.

Factory Testing: All equipment undergoes rigorous debugging and testing to ensure reliable performance.

Supporting Documents: Detailed equipment manuals, operation and maintenance guides, and spare parts lists are provided to the customer.

Transportation: By land or sea, with packing lists and container loading diagrams supplied.

Delivery Options: Offers both complete machine delivery and component shipment, with support for on-site assembly by the customer.

Optional Configurations: Each HZS25 batching plant is customized to meet the customer's specific needs. Variations in configuration mean every HZS25 plant is unique!

Service

Technical Support: Installation, commissioning, and operation training are provided.

Warranty: 12-month warranty for the main machine, excluding wear parts.

Spare Parts Supply: Genuine spare parts are kept in stock for quick response to customer needs.

Remote Support: Online troubleshooting and remote control services help customers resolve issues promptly.

Installation & Commissioning: Remote technical support is available, or experienced engineers can be dispatched on-site as needed.

FAQ

1. Is the HZS25 concrete batching plant suitable for export?

Yes, the HZS25 is a standard export model. It complies with international shipping and installation standards, and can be customized to match the voltage and frequency requirements of the destination country.

2. How much concrete can the HZS25 produce per day?

Theoretical capacity is 25 cubic meters per hour. Based on an 8-hour working day, it can produce approximately 200 cubic meters of concrete per day.

3. Do you provide installation and commissioning services?

Yes. We can dispatch technical personnel to the customer's site for installation guidance and operator training.

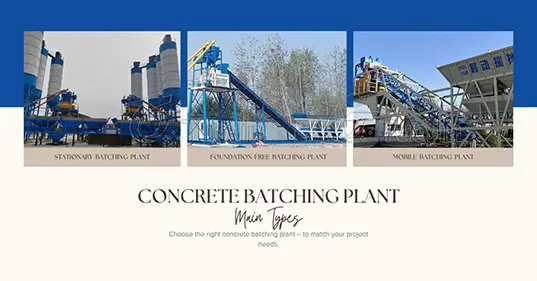

4. Can the HZS25 be upgraded to a mobile batching plant?

The HZS25 is a stationary structure. If mobility is required, we recommend the YHZS25 mobile batching plant, which has a compact design and is easy to relocate.

5. What is the price range of concrete batching plants made in China?

Prices vary depending on the model, configuration, and production capacity. Small batching plants generally range from USD 20,000 to 50,000, medium-sized ones from USD 50,000 to 100,000, and large-scale plants can reach USD 150,000 or more. Specific quotes are customized based on customer requirements.

6. Is the quality of concrete batching plants made in China reliable?

Yes. Concrete batching plants made in China are technologically mature and widely exported to Southeast Asia, the Middle East, Africa, South America, and other regions. They enjoy a strong reputation in the international market.

7. Do you support OEM or private label manufacturing?

Many Chinese manufacturers offer OEM/ODM services. They can customize the appearance, color, logo, and control system language according to customer needs, making them ideal for overseas clients looking to expand their brand.