What is a cement silo?

A cement silo, also known as a cement tank, is a key component of a concrete batching plant used for storing bulk powder materials such as cement, fly ash, and slag powder. It features excellent sealing performance, strong structure, flexible installation, and easy operation. Cement silos are widely used in ready-mix concrete plants, precast factories, cement product plants, as well as in construction materials, chemical, and grain storage industries.

How do cement silos work?

Bulk cement or other powder materials are delivered into the silo through a pressurized pipeline from a bulk cement tanker.

The dust collector on the top cover filters and discharges excess air to prevent dust pollution.

Materials are discharged through the cone-shaped bottom outlet and conveyed to the mixer via a screw conveyor.

Level indicators continuously monitor the material level inside the silo, with high/low-level alarms to prevent overfilling or material shortage.

If material blockage occurs, the arch-breaking device helps loosen the material to ensure smooth discharge.

Parts of Cement Silos

Silo Body: Cylindrical steel structure composed of a top cover, vertical shell, and conical bottom. The surface is treated with anti-corrosion paint.

Top Cover: Equipped with safety guardrails, feeding port, manhole, and dust collector interface.

Cone Section: Designed for material discharge, typically with a 60°–70° angle to allow smooth gravity flow.

Support Legs/Base: Steel columns that support the entire silo, usually configured with four or eight legs.

Dust Collector: Mounted on the top cover to prevent dust emission during filling and discharge.

Arch-Breaking Device: Uses pneumatic vibration or air fluidization to prevent powder bridging and clogging.

Level Indicator: Detects high and low material levels for intelligent monitoring.

Discharge System: Located at the bottom with an outlet flange for connection to a screw conveyor.

Advantages & Features

Excellent Sealing: Welded and sealed body prevents dust leakage and moisture intrusion.

Sturdy Structure: Made of high-strength steel plates for durability and long service life.

Modular Design: Allows for sectional transport and on-site assembly, ideal for export or space-limited projects.

Customizable: Flexible options for capacity, material, discharge type, and more.

Easy Maintenance: Simple structure for convenient inspection and cleaning.

High Safety: Equipped with ladder, guardrail, safety valve, and level alarm for safe operation.

Technical Specifications

| Size | 50T | 100T | 150T | 200T | 300T | 400T | 500T | 800T | |

|---|---|---|---|---|---|---|---|---|---|

| Diameter | 3160mm | 3160mm | 3160mm | 4500mm | 5300mm | 6800mm | 6800mm | 8000mm | |

| Silo height | 6.5m | 10.7m | 15m | 11.5m | 12.7m | 11.7m | 13.5m | 15.3m | |

Diameter of landing leg material | Φ219✖5m | Φ219✖6m | Φ273✖6m | Φ273✖8m | Φ325✖8m | Φ325✖8m | Φ325✖10m | Φ426✖12m | |

Center distance of each landing leg | 2240mm | 2240mm | 2240mm | 3160mm | 3748mm | 4800mm | 3400mm | 3060mm | |

| Weight | 4T | 5.5T | 8T | 12T | 17T | 21T | 28T | 45T | |

Main Applications of Cement Silo

Used for storing bulk powder materials such as cement, fly ash, slag powder, and silica fume.

Works together with a screw conveyor to achieve automatic material transfer from storage to mixer.

Ensures continuous material supply for the batching plant, improving production efficiency.

Prevents moisture and caking, extending the storage life of materials.

Usage and Maintenance Tips

Regularly check the working condition of the level indicator, arch-breaking device, and electrical control system.

Avoid overpressure feeding to prevent damage to the silo top.

Clean the dust collector filters regularly to ensure smooth ventilation.

Perform anti-corrosion inspections: repaint any peeled coating areas promptly to prevent rust.

Prevent moisture: ensure the silo cover is well-sealed and the silo body has no water leakage points.

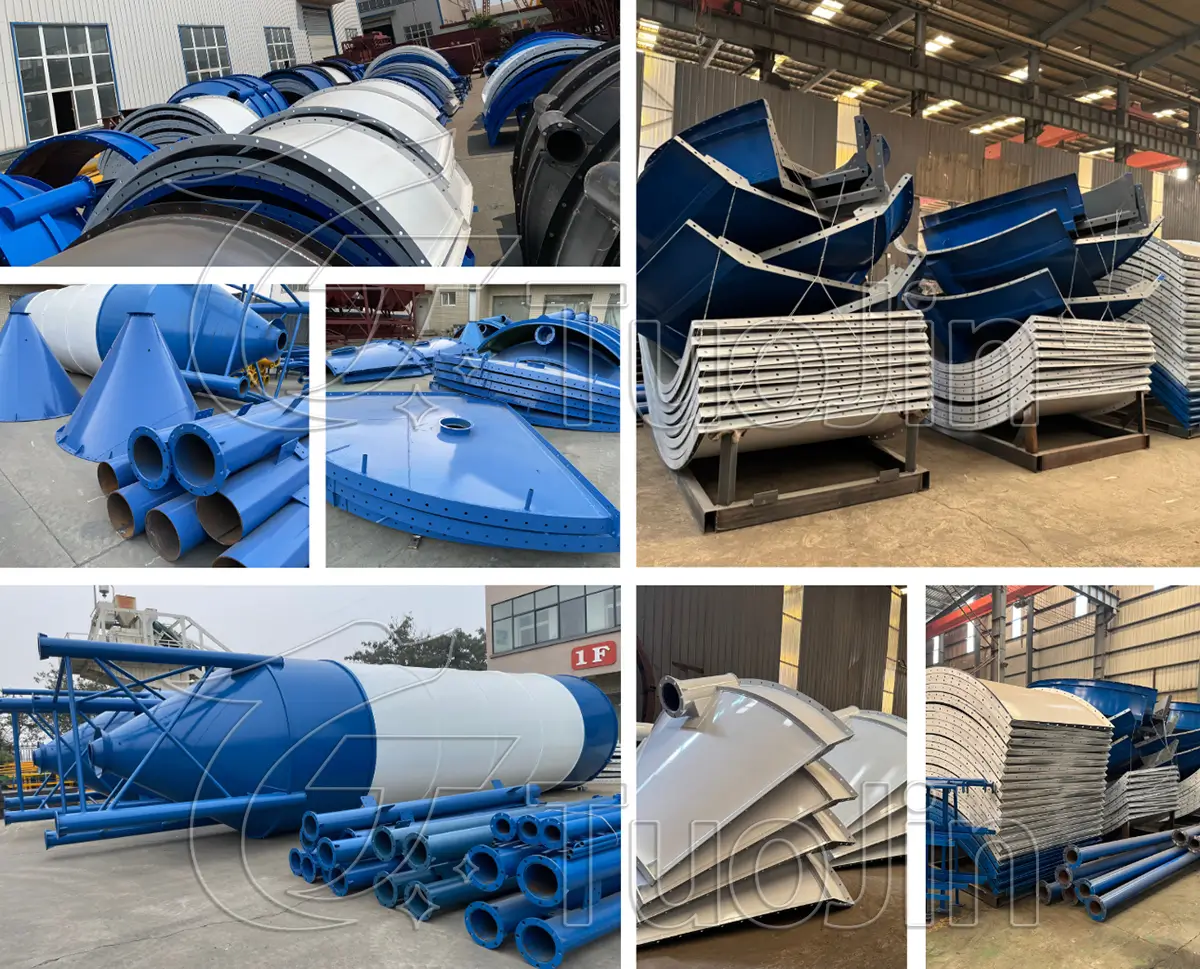

Transportation and Installation

Small cement silos (≤50 tons) can be transported as a whole and lifted directly into place.

Large cement silos (≥100 tons) are usually delivered in sheet form and assembled on-site with bolts.

During installation, foundation anchor bolts must be prepared in advance to ensure the legs are vertically aligned and securely fixed.

After installation, pressure tests, ventilation checks, and function debugging should be carried out to ensure proper operation.

Factory delivery of Cement Silo

Production Lead Time: Typically 7–15 working days, depending on the specific order requirements.

Packaging Method: Standard export packaging with reinforced protection for key components.

Factory Testing: All equipment undergoes rigorous debugging and testing to ensure reliable performance.

Supporting Documents: Detailed equipment manuals, operation and maintenance guides, and spare parts lists are provided to the customer.

Transportation: By land or sea, with packing lists and container loading diagrams supplied.

Delivery Options: Offers both complete machine delivery and component shipment, with support for on-site assembly by the customer.

Optional Configurations: Each cement silo is customized to meet the customer's specific needs. Variations in configuration mean every cement silo is unique!

Service

Pre-sales Consultation: Professional advice to help you select the equipment that best suits your needs.

Customization: Tailor-made solutions to meet specific project requirements.

Installation and Commissioning: Remote technical support available, or experienced engineers can be dispatched for on-site installation guidance when necessary.

After-sales Support: Comprehensive warranty and technical support to ensure smooth operation of your equipment.

Spare Parts Supply: Prompt availability of original spare parts to minimize downtime.

FAQ

1. How much does a cement silo cost?

The price of a cement silo varies depending on capacity, material (carbon steel, stainless steel), configuration (welded or bolted), and additional equipment (dust collector, level indicator, etc.). Generally, prices range from $3,000 to $15,000 USD. For an accurate quote, please contact us with your specific requirements.

2. Where can I buy a cement silo?

You can buy high-quality cement silos directly from trusted manufacturers or authorized suppliers. TuoJin Machinery is a professional China cement silo manufacturer, offering competitive factory prices, fast delivery, and global shipping.

3. Do you have cement silos for sale?

Yes, we offer a wide range of cement silos for sale, including 30T, 50T, 100T, 150T, and custom capacities. Both welded and bolted types are available to suit your project size and shipping method.

4. How to choose a reliable cement silo factory?

Look for a manufacturer with ISO certification, export experience, and professional after-sales service. A good cement silo factory should offer customization options, provide installation guidance, and guarantee product quality. We have over 30 years of production experience and export to more than 30 countries.

5. What are the advantages of choosing a China cement silo factory?

China cement silo factories offer competitive prices, fast delivery, flexible customization, and a full range of sizes. Many have rich export experience and provide reliable after-sales support, making them a cost-effective and dependable choice for global buyers.