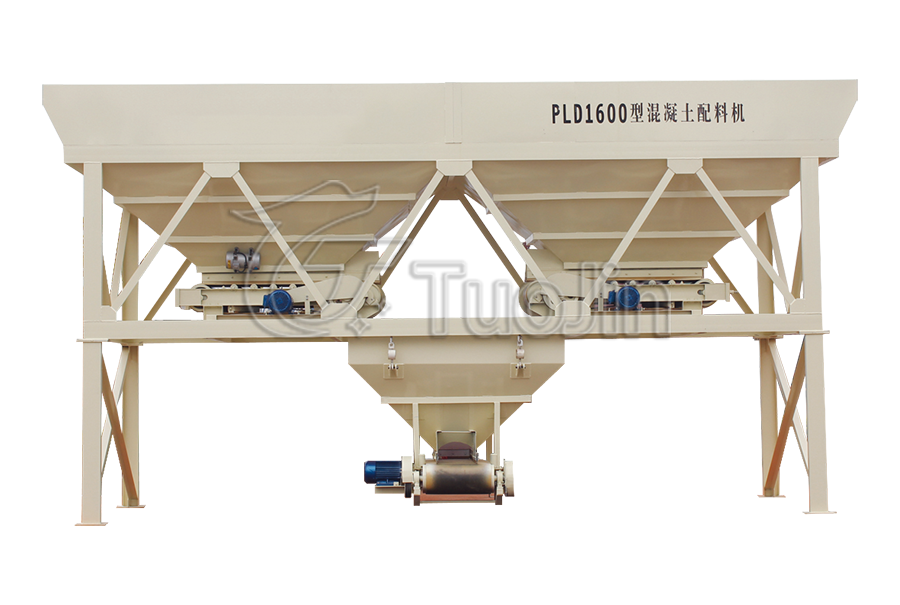

Product Description

Aggregate batcher, also known as the aggregate batching system, is an automated device that automatically weighs and delivers different specifications of sand and stone aggregates according to the set proportions based on the concrete mix design. It is commonly part of a complete concrete batching plant system, working in conjunction with the concrete mixer, conveyor system, control system, and other components.

Working Principle

1. The operator inputs the desired concrete mix design into the control system.

2. The batching machine automatically opens the discharge gates of each bin according to the mix instructions.

3. Aggregates of different specifications flow into the weighing hopper according to their respective proportions.

4. Once the set weight is reached, the discharge gates are automatically closed.

5. After weighing is completed, the aggregates are conveyed to the mixer for mixing through a belt conveyor.

Parts of Aggregate Batcher

1. Storage Hoppers (Aggregate Bins)

Available in various configurations such as 2-bin, 3-bin, and 4-bin models, each bin is used to store different types of aggregates such as fine sand, medium sand, and crushed stone.

The storage hoppers are made of welded steel structures and equipped with discharge outlets and pneumatic or electric gates at the bottom to control material flow.

2. Weighing System

Consists of a weighing hopper, load cells (weighing sensors for accurate material measurement), and a pneumatic system.

There are two types of weighing: independent weighing and cumulative weighing, with independent weighing offering higher precision.

3. Conveying System

Typically uses a belt conveyor or inclined belt conveyor to transport the weighed aggregates to the feeding hopper of the concrete mixer.

4. Control System

The automatic control system carries out the batching process based on the preset mix ratio and production requirements, precisely managing the weighing and delivery of materials.

Advanced systems are equipped with touch screens, PLC program control, human-machine interfaces (HMI), and support features like remote monitoring and fault alarms.

Aggregate batcher classification

1. By weighing method

Cumulative weighing batching machine: Aggregates from multiple bins are weighed sequentially in a single weighing hopper.

Independent weighing batching machine: Each aggregate bin has its own weighing hopper, offering higher weighing accuracy.

2. By number of bins (model)

Models include PLD800, PLD1200, PLD1600, PLD2400, PLD3200, PLD4800, etc.

The number represents the total theoretical weighing capacity. Common configurations include 2-bin, 3-bin, and 4-bin types.

3. By control method

Manual control type: Suitable for small construction sites; low cost but lower efficiency.

Automatic control type: Suitable for medium and large batching plants; offers high efficiency and accuracy.

Advantages & Features

High weighing accuracy: Equipped with high-precision sensors and intelligent control systems to ensure accurate batching.

High level of automation: Fully automatic operation reduces manual intervention and improves production efficiency.

Strong adaptability: Suitable for automatic batching of various sand and stone aggregates.

Rational structure and easy maintenance: Modular design allows for convenient inspection and maintenance.

Good compatibility: Can be flexibly matched with various types of concrete mixers and control systems.

Excellent scalability: The number of bins and weighing methods can be adjusted according to production requirements.

Technical Specifications

| Model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 | |

|---|---|---|---|---|---|---|---|

| Weighing hopper | 800L | 1200L | 1600L | 2400L | 3200L | 4800L | |

| Storage hopper | 2✖2.5m³ | 3✖5m³ | 3✖5m³ | 4✖17m³ | 4✖23m³ | 4✖30m³ | |

| Productivity | 48m³/h(Dry ingredients) | 56m³/h(Dry ingredients) | 75m³/h(Dry ingredients) | 150m³/h(Dry ingredients) | 200m³/h(Dry ingredients) | 300m³/h(Dry ingredients) | |

| Weighing accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | |

| Maximum weighing | 3000kg | 3000kg | 3000kg | 4500kg | 4500kg | 6000kg | |

| Number of ingredients | 2-3kinds | 2-4kinds | 2-4kinds | 2-4kinds | 2-4kinds | 2-4kinds | |

| Feeding height | 2450mm | 2950mm | 2950mm | 3700mm | 4000mm | 5000mm | |

| Speed of feeding belt conveyor | 1.6m/s | 1.6m/s | 1.6m/s | 1.6m/s | 1.6m/s | 2m/s | |

| Power | 3✖3kw=9kw | 4✖3kw=12kw | 4✖3kw=12kw | 11kw | 11kw | 15kw | |

| Total weight | 2450kg | 4500kg | 4500kg | 8500kg | 10200kg | 14000kgs | |

| Overall Dimensions | 5600✖1650✖2950mm | 9400✖2100✖3450mm | 9400✖2100✖3450mm | 14500✖3250✖4000mm | 14500✖3450✖4500mm | 16500✖3500✖4750mm | |

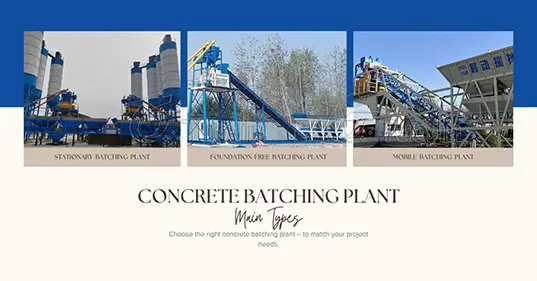

Applications

Various types of stationary concrete batching plants (e.g., HZS series)

Mobile batching plants

On-site construction projects such as highways, bridges, tunnels, and water conservancy projects

Commercial concrete production enterprises

Special environment applications, such as extremely cold regions and desert/dry area construction

Factory delivery of Aggregate Batcher

Production Lead Time: Typically 7–15 working days, depending on the specific order requirements.

Packaging Method: Standard export packaging with reinforced protection for key components.

Factory Testing: All equipment undergoes rigorous debugging and testing to ensure reliable performance.

Supporting Documents: Detailed equipment manuals, operation and maintenance guides, and spare parts lists are provided to the customer.

Transportation: By land or sea, with packing lists and container loading diagrams supplied.

Delivery Options: Offers both complete machine delivery and component shipment, with support for on-site assembly by the customer.

Optional Configurations: Each aggregate batcher is customized to meet the customer's specific needs. Variations in configuration mean every aggregate batcher is unique!

Which aggregate batcher to choose?

When selecting a batching machine, the following factors should be considered comprehensively:

Required concrete production capacity (match with the mixer or batching plant model)

Number of aggregate types (determines the number of bins)

Accuracy requirements for weighing (choose between independent or cumulative weighing)

Control system preferences (automatic or manual)

Site layout and civil foundation conditions

Routine Maintenance and Care

Regularly check whether the discharge gates of each bin operate smoothly without jamming.

Clean residual materials from the weighing hopper to ensure sensor accuracy.

Inspect the pneumatic system and solenoid valves for proper functioning.

Calibrate the weighing system to maintain long-term accuracy.

Ensure dust-proof and rain-proof protection to extend the equipment's service life.

FAQ

1. How many types of aggregates can a batching machine handle?

A standard batching machine can handle 2 to 4 different types of aggregates. The most common configurations are 3-bin or 4-bin models. For special requirements, custom machines with more than 5 bins can also be manufactured.

2. How is batching accuracy ensured? Is regular calibration necessary?

The batching machine uses high-precision weighing sensors and an automatic control system, with an accuracy of up to ±2%. To maintain long-term accuracy, it is recommended to calibrate the weighing system every 3 to 6 months, or after changing the types of aggregates.

3. How much aggregate batching concrete?

The amount of aggregate used in concrete batching depends on the specific concrete mix design and production capacity of the batching plant.

4. What is the difference between cumulative weighing and independent weighing? How should I choose?

Cumulative weighing means all aggregates are weighed one after another in a single weighing hopper. It features a simple structure and lower cost, suitable for small-scale plants.

Independent weighing means each type of aggregate is weighed separately. It offers higher precision and better efficiency, making it suitable for medium to large plants or projects with higher concrete quality requirements.

Selection should be based on project needs and budget.

5. Which models of mixers are compatible with the batching machine?

The batching machine model must match the capacity of the mixer. For example:

PLD800 → JS500

PLD1200 → JS750

PLD1600 → JS1000

PLD2400 → JS1500

PLD3200 → JS2000

PLD4800 → JS3000

For detailed matching, please refer to the product manual or consult technical support.

6. What should I do if the weighing is inaccurate or has large errors during use?

We recommend troubleshooting as follows:

Check whether the weighing sensor is damaged or obstructed.

Confirm whether the pneumatic discharge gate closes properly and if there’s any material leakage.

Check the control system parameters for abnormalities.

If the problem persists, please contact the manufacturer's after-sales technical support.